How to Choose the Right Refrigerated Shipping Container for Your Needs

In today's global market, the demand for refrigerated shipping containers is steadily increasing. According to a recent report by the International Refrigerated Transportation Association, the growth rate for this sector is projected to be 8% annually. Businesses often rely on these containers to transport perishable goods safely.

Choosing the right refrigerated shipping container can significantly impact product quality and shelf life. A survey indicated that improper container selection led to 23% of spoiled shipments last year. This statistic underscores the necessity for informed decision-making. Container size, insulation, and temperature control play pivotal roles.

However, the vast array of options can be overwhelming. Many companies find themselves questioning their needs versus available solutions. The container's features must align with the specific requirements of the cargo. Reflecting on past experiences can guide future choices, emphasizing the importance of deliberate consideration in container selection.

Understanding Refrigerated Shipping Containers and Their Uses

Refrigerated shipping containers play a vital role in global logistics. They ensure the safe transport of perishable goods. These containers can maintain temperatures ranging from -30°C to +30°C. According to industry reports, the refrigerated shipping container market is projected to grow by 7% annually. This growth aligns with the increasing demand for fresh food products worldwide.

Understanding the uses of these containers is essential. They are not just for food. Pharmaceuticals and chemicals also benefit from controlled temperatures. The right container can prevent spoilage, ensuring that goods arrive in peak condition. Yet, choosing the right option isn't always straightforward. Factors like size, cooling technology, and insulation matter significantly.

It's crucial to assess your specific needs. A mismatch could lead to waste. For example, undercooling may result in product degradation. Conversely, overcooling wastes energy and can increase costs. Data shows that approximately 25% of refrigerated shipments suffer losses due to improper temperature management. Balancing these factors can be challenging but is necessary for successful shipping.

Factors to Consider When Choosing a Refrigerated Shipping Container

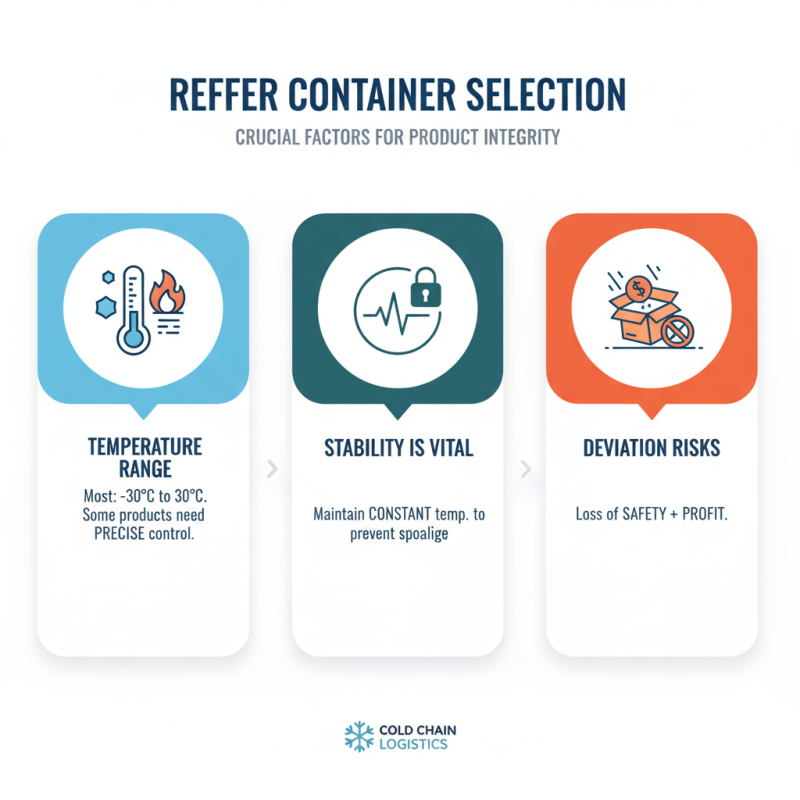

When selecting a refrigerated shipping container, several crucial factors come into play. The temperature range is essential. Most refrigerated containers operate between -30°C to 30°C. However, specific products may require precise conditions. According to industry standards, maintaining a stable temperature is vital for product integrity. Any deviation can lead to spoilage, affecting both safety and profit margins.

Container size also matters. The capacity typically ranges from 20 to 40 feet. Choose a size that matches your shipping volume. Overloading may cause inefficiencies. A report from the Transportation Intermediaries Association highlighted that 25% of shipments are improperly loaded, leading to increased costs.

Ventilation is another critical component to examine. Some products need airflow while others require a more controlled environment. The South African Cold Chain Logistics report stated that proper airflow reduces moisture build-up, which can spoil goods. Taking the time to evaluate these factors can help ensure the right choice, lessening the risk of costly mistakes.

Types of Refrigerated Shipping Containers: Options and Features

When selecting a refrigerated shipping container, it's essential to understand the types available. Common options include standard reefer containers, which maintain temperatures between -20°C and +20°C. These containers are ideal for perishable goods like fruits and vegetables. Another type is the high cube reefer, offering extra internal height. This is useful for shipping tall items or maximizing space. According to industry reports, about 38% of all refrigerated containers are high cube models.

Additionally, specialty containers cater to specific needs. Some come equipped with multi-temperature zones, allowing for diverse cargo types in one trip. This flexibility can enhance operational efficiency. Data suggests that using multi-temperature containers can reduce logistics costs by up to 15% compared to single-temperature units. However, these advanced features may complicate maintenance and operation, warranting careful consideration.

Beyond the type of container, the insulation level plays a critical role. Better insulation can maintain temperature longer during transit, reducing energy consumption. However, higher quality insulation often leads to increased initial costs. Shipping managers must weigh these factors against their budget and cargo needs. Each choice carries unique implications that could affect product quality and delivery timelines. Understanding these details can significantly impact shipping success.

Evaluating Size and Capacity Requirements for Your Shipping Needs

When selecting a refrigerated shipping container, think about size and capacity. You must assess the volume of goods you plan to transport. A standard container might be too small if you have high volumes. Measuring your items can help determine the right fit.

Tip: Create a list of your products. Include dimensions and weight. This will clarify what you need.

Consider the temperature range. Some items require specific temperatures. For example, seafood needs cooler conditions than produce. Your choice should align with these requirements.

Tip: Be cautious with estimations. Overestimating may lead to wasted space. Underestimating can cause spoilage.

Remember, not all containers are equal. Check for insulation quality, door access, and ventilation. These factors can impact your cargo's condition upon arrival.

Tip: Ask for expert advice if unsure. It's better to ask questions than to make mistakes.

Refrigerated Shipping Container Size and Capacity Requirements

This chart illustrates the various capacities of refrigerated shipping containers based on different sizes. The data reflects the common sizes available in the market and their respective capabilities in terms of volume and typical load capacity.

Cost Considerations and Budgeting for Refrigerated Shipping Solutions

When budgeting for refrigerated shipping solutions, it’s crucial to consider various factors. The initial cost of the shipping container can vary greatly. Standard containers may seem cheaper upfront. However, investing in a high-quality model can reduce long-term costs. Maintenance fees, energy consumption, and repair expenses should also be considered.

Look at your specific needs. What products are you shipping? How long will they be in transit? These questions impact your budget significantly. A temporary solution may seem appealing, yet it could lead to unexpected costs. Inadequate cooling can spoil your goods. Choose wisely.

Evaluate potential hidden costs. Consider insurance, customs fees, and transportation fees. These can add up quickly. It’s essential to identify all possible expenses. A well-planned budget can save you from future financial strain. Reflecting on these details ensures that you choose a shipping solution that fits your operational needs and financial capacity.

Related Posts

-

2025 Top 5 Cargo Shipping Container Innovations You Can't Miss

-

Why Choose a Box Container for Your Shipping and Storage Needs?

-

How to Choose the Right Large Shipping Container for Your Needs?

-

How to Manage Empty Shipping Containers Effectively and Save Costs

-

How to Choose the Best 10 Foot Storage Container for Your Needs

-

Top 10 Uses for 10ft Shipping Containers You Need to Know