2026 Top Trends in Refrigerated Container Technology for Safe Transport?

In the rapidly evolving world of logistics, refrigerated containers have become essential for safe transport of temperature-sensitive goods. According to a recent market analysis by Transparency Market Research, the global refrigerated container market is projected to reach $5.2 billion by 2026, reflecting a significant demand surge. As products such as pharmaceuticals and perishables require strict temperature control, advancements in refrigerated container technology are vital.

Expert in the field, Dr. Emily Harper, emphasizes the importance of innovation: “Refrigerated containers must not only keep products cold but also ensure efficiency and reliability.” This highlights a pressing challenge within the industry. While the transportation of goods has drastically improved, issues like energy consumption and maintenance costs remain critical considerations. Companies need to adopt technologies that align with sustainability goals while maintaining operational efficiency.

As we look toward 2026, trends such as IoT integration and automated monitoring systems are set to revolutionize refrigerated container technology. However, industry leaders must address the balance between cutting-edge features and practical, user-friendly designs. Emphasizing both safety and efficiency is crucial for the future of refrigerated transport.

Emerging Innovations in Refrigerated Container Design for 2026

In 2026, innovations in refrigerated container design will transform transport. Sustainability is a key focus. Containers will feature energy-efficient cooling systems, reducing environmental impact. Improved insulation technology will better maintain temperature, ensuring food safety.

Smart technology is emerging. Advanced sensors will monitor conditions in real-time. These devices will alert operators to temperature changes. This capability will help prevent spoilage during transport. Imagine receiving updates directly to your phone.

Tip: Choose containers with robust insulation if you're transporting perishable items in hot weather. Check reviews for reliability. Not all containers are built the same. Some may underperform, leading to costly losses. Being cautious is essential in this evolving market.

2026 Top Trends in Refrigerated Container Technology

Advancements in Temperature Control Technologies for Safe Transport

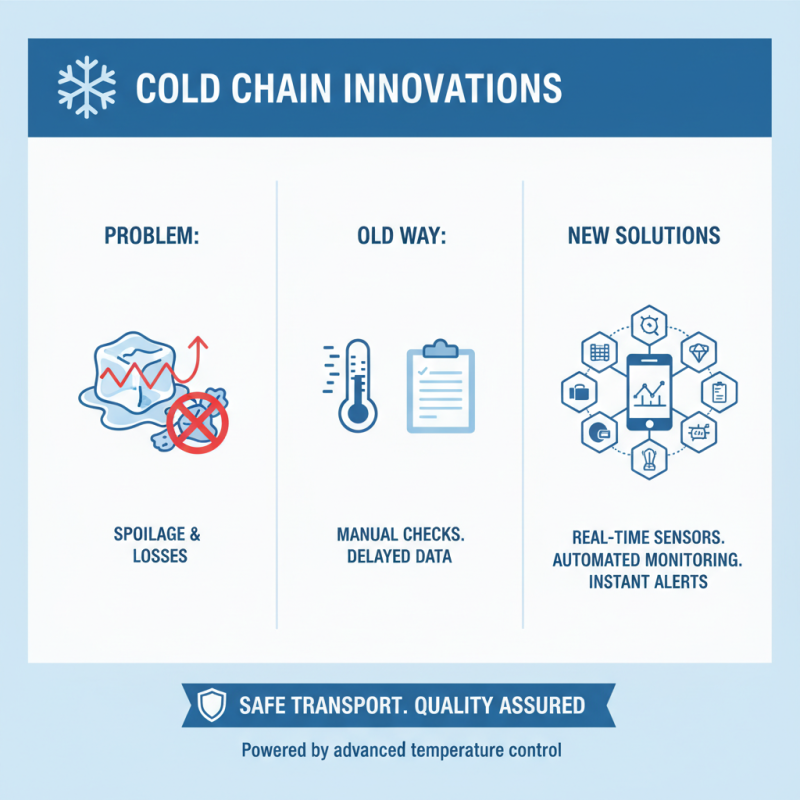

Temperature control technology has seen remarkable advancements in recent years. These improvements are essential for transporting goods safely. Cold chain management ensures products remain at optimal temperatures, reducing spoilage. New sensors provide real-time data on temperature fluctuations. This instant feedback helps prevent potential losses.

Insulation materials have also evolved. They are now lighter yet more effective. This change boosts energy efficiency during transport. However, there are still challenges to address. For instance, some containers may fail to maintain consistent temperatures. Identifying these weak points is crucial for future developments.

Automation plays a significant role in temperature control. Automated systems can adjust settings based on external conditions. Yet, reliance on technology poses risks. System failures could lead to critical temperature shifts. Continuous monitoring remains vital to ensure safety. Embracing these advancements requires careful consideration and ongoing improvements.

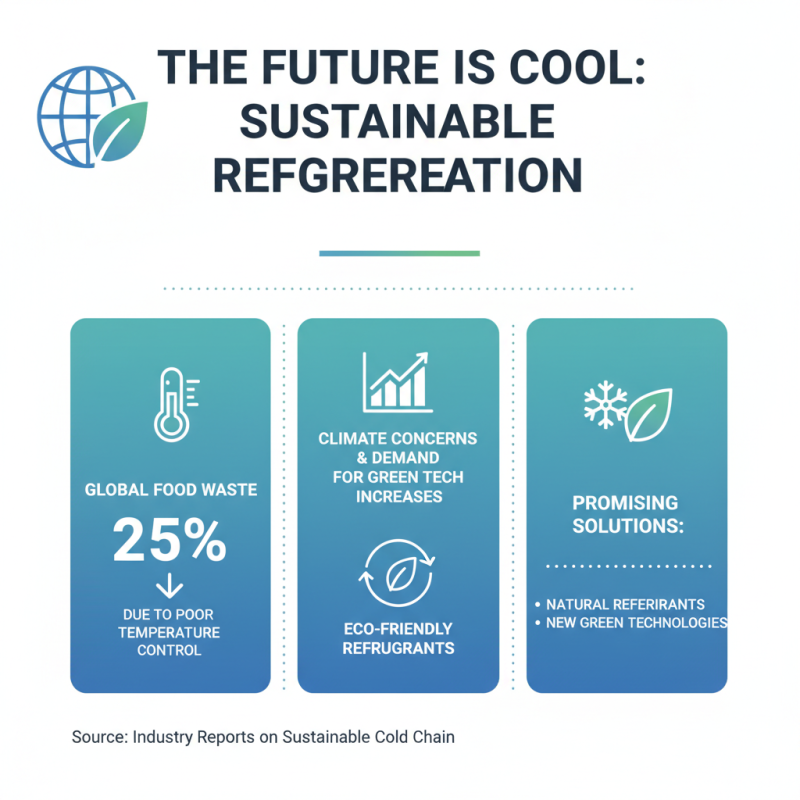

Sustainable Refrigeration Solutions for Environmental Compliance

The demand for sustainable refrigeration solutions is rising. Industry reports indicate that refrigerated transport accounts for nearly 25% of global food waste due to inadequate temperature control. This is alarming. As climate concerns grow, the need for eco-friendly refrigerants becomes critical. New green technologies, like natural refrigerants, offer promising alternatives.

Many companies are exploring ammonia and carbon dioxide systems. These options are not only effective but also comply with stricter environmental regulations. However, challenges remain. An increase in system efficiency might lead to higher upfront costs. This requires careful consideration, especially for smaller businesses.

Data shows that around 40% of refrigerated containers currently use HFCs, which contribute significantly to greenhouse gas emissions. Transitioning to sustainable options is essential. But, achieving this transition is complex and may involve trial and error. With the right strategies, the industry can find a balance between performance and environmental responsibility. The path ahead is not straightforward, and continual refinement is necessary.

Integration of IoT in Monitoring Refrigerated Containers

The integration of IoT in monitoring refrigerated containers is a game changer.

With connected sensors, temperature and humidity conditions can be tracked in real-time. This technology provides

critical data during transport. It helps ensure that perishable goods remain safe.

Tips: Regularly check sensor accuracy for optimal performance.

Use alerts to notify staff about temperature deviations.

IoT not only enhances safety but also increases efficiency. Improved visibility allows companies to make informed

decisions. However, managing large data sets can be overwhelming. Teams must be equipped to handle this influx

of information.

Tips: Set up a streamlined data management system.

Invest in training for staff to interpret IoT data effectively.

Challenges arise with software glitches or connectivity issues. Not all locations have strong internet signals.

Therefore, backup plans must be in place. By anticipating these challenges, organizations can mitigate risks.

Future Challenges and Opportunities in Refrigerated Supply Chains

The refrigerated supply chain faces notable challenges ahead. As demand for fresh produce rises, maintaining product integrity becomes crucial. Temperature fluctuations can lead to spoilage, affecting profits and food safety. According to industry reports, nearly 30% of perishable goods are lost due to improper refrigeration.

Innovations in refrigerated container technology offer solutions. Advanced monitoring systems can ensure optimal conditions during transport. These technologies provide real-time tracking of temperature and humidity levels. Reports show a potential 15% reduction in spoilage rates with improved monitoring.

**Tips:** Regular training for personnel handling these containers is vital. Awareness of procedures helps mitigate risks. Additionally, investing in sustainable designs for refrigerated containers can support environmental goals while meeting demand. Assessing the technology’s performance regularly will reveal areas for improvement, increasing efficiency in operations. Regular audits can help identify gaps in the supply chain, reducing potential losses.

2026 Top Trends in Refrigerated Container Technology for Safe Transport

| Trend | Description | Impact on Supply Chain | Challenges | Opportunities |

|---|---|---|---|---|

| IoT Integration | Utilizing Internet of Things technology for real-time monitoring of temperature and humidity levels. | Improved visibility and control over the supply chain. | High initial investment and technological barriers. | Enhanced data analytics for decision-making and operational efficiency. |

| Energy Efficiency | Development of refrigerants and insulation materials that reduce energy consumption. | Lower operational costs and reduced carbon footprint. | Regulatory compliance with environmental policies. | Potential for sustainable branding and increased customer demand. |

| Blockchain Technology | Implementing blockchain for traceability and security in the supply chain. | Enhanced trust and accountability among stakeholders. | Complexity of integration and industry adoption. | Improvement in fraud detection and product authenticity. |

| Smart Container Technology | Containers equipped with advanced sensors and controls for efficient temperature management. | Increased product integrity and reduced spoilage rates. | High costs of smart equipment and maintenance. | Opportunity for product differentiation and premium pricing. |

| Automated Logistics | Use of robotics and automated systems for handling and transporting refrigerated goods. | Greater efficiency and reduced labor costs. | Resistance to change from workforce and training needs. | Creation of more agile supply chain structures and faster response times. |

Related Posts

-

Top 10 Cold Storage Containers for Efficient Temperature Control Solutions

-

2025 Top Considerations for Choosing a 6ft Shipping Container for Your Needs

-

How to Choose the Right Large Shipping Container for Your Needs?

-

How to Choose the Right Sea Container for Your Needs?

-

How to Choose the Best 10 Foot Storage Container for Your Needs

-

Why Choose a Box Container for Your Shipping and Storage Needs?